Welcome

NOW NEW: LEARN EVERYTHING ABOUT CHROMIUM(III) SALT SOLUTIONS –

THE BLUE-GREEN ALTERNATIVE FROM THE GEFAHRSTOFFZENTRUM KAISERSLAUTERN.

WELCOME TO OUR WEBSITE!

Thank you for your interest in our company.

The business area of Gefahrstoffzentrum (GSZ) Kaiserslautern GmbH is contract service provision for the production, filling, storage and picking of chemical/technical products. The objective of the company is the optimization of processes in consideration of all environmentally relevant issues and simultaneously the long-term and secure procurement of jobs

DIETMAR STRAUB

CEO

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Informationpallet spaces for general chemical products in observance of association requirements (VCI)

spatially separated storage sections for the sorted provision of designated storage classes

m² storage space

employees

ALL-IN- ONE PACKAGE

Our technical know-how and our experience allow us to offer services ranging from production to storage all the way to logistics.

YOUR PARTNER – THE GSZ

Our past cooperation with our industrial partners certifies our professional positioning on the market and very high customer satisfaction rate with respect to our professional competence.

HAZARDOUS SUBSTANCES STORAGE

Gefahrstoffzentrum (GSZ) Kaiserslautern GmbH has approval for the storage of chemical products in accordance with the German Federal Immission Control Act (BImSchG) in conjunction with the 4th Federal Immission Control Ordinance (BImSchV), Annex No. 9.35

solids toll manufacturing

liquids toll manufacturing

Our liquids production has stainless steel and plastic mixing vessels used for the batch production of liquid preparations

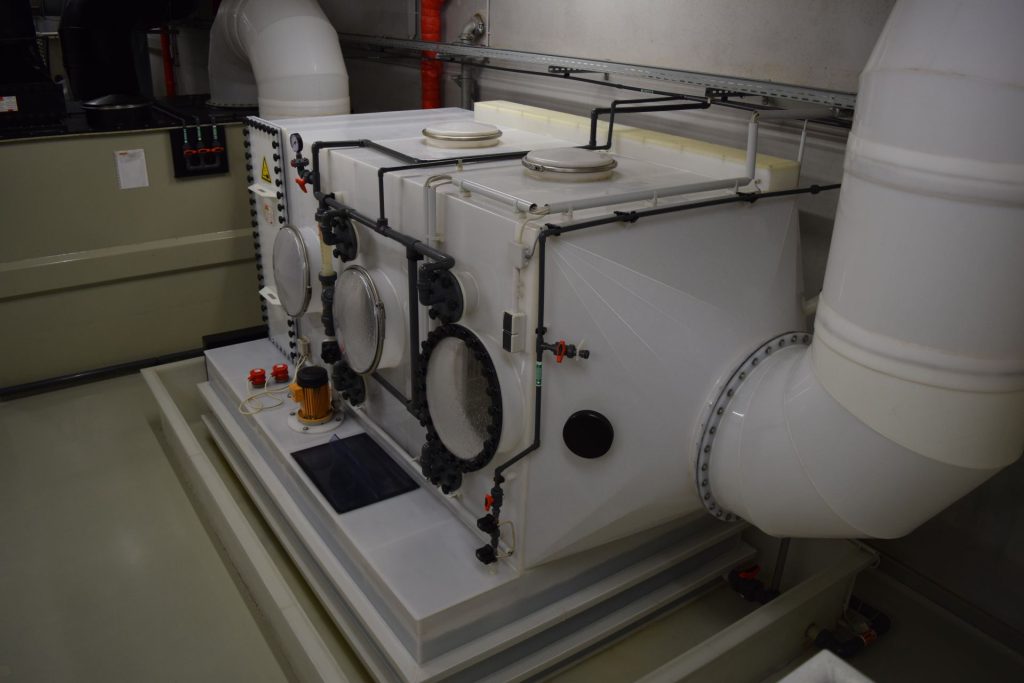

AIR WASHERS FOR ALL PRODUCTION AREAS

Thanks to our air washer, we guarantee the detention of substances harmful to health and the environment so that no hazardous substances can be released into the environment.

QUALITY CONTROL

Thanks to our in-house quality control, we ensure at all times that both the delivered raw materials and the end products are of the required quality for our customers. Our internal quality management system

Hazardous incident prevention

Information for the neighbours of the Gefahrstoffzentrum (GSZ) Kaiserslautern GmbH and the public according to Sec. 11 of the Hazardous Incident Ordinance

Last News

faq

WHY CHOOSE A HAZARDOUS INCIDENT FACILITY?

The advantages are:

- Official approval of production, storage and safety equipment.

- Minimum risk despite a high volume of hazardous substances thanks to compliance with various regulations on environmental protection, storage and hazardous substance handling.

- Immediate assistance assured in case of an emergency thanks to instructed firefighters.

- Regular controls by authorities and experts in hazardous goods law allow adjustments to conform to current directives and regulations.

- Production with large quantities of raw materials subject to labelling requirements that normal chemical operations are not permitted to carry out.

- Large quantities of hazardous substances may be stored (e.g. 1,000 t of substances labelled as toxic)